A smoother future for Antifouling coatings

Hidden just below the ocean’s surface, a stone’s throw away from a popular tourist ferry near Amsterdam, lies a metal frame with a peculiar collection of dinner-plate sized squares covered in algae, mussels and small crustaceans. Were it not for the safety gear of the people inspecting them, you might think it was an artwork being grown for the grand foyer of a nearby tech company. These ‘inspectors’ are actually researchers, and their interest is the growth which clings so persistently to the plates.

One of the researchers is Dr. Maria Salta, a marine biologist who specialises in the marine life which has managed to attach itself to these plates, even though each has been painted with an antifouling coating designed to actually prevent algae and other marine organisms from grabbing hold.

The plates are used to simulate the hulls of boats like the nearby ferry which, unbeknown to the happy tourists on the top deck, is continuously collecting a vast assortment of marine life along its belly. This particular set of plates is static, therefore simulating the hull of a ship in port to see how much growth attaches. The more marine life which is able to attach, the higher the drag coefficient of the boat, the more fuel it burns, the more greenhouse gasses (GHG) it emits, and the more money it costs to operate.

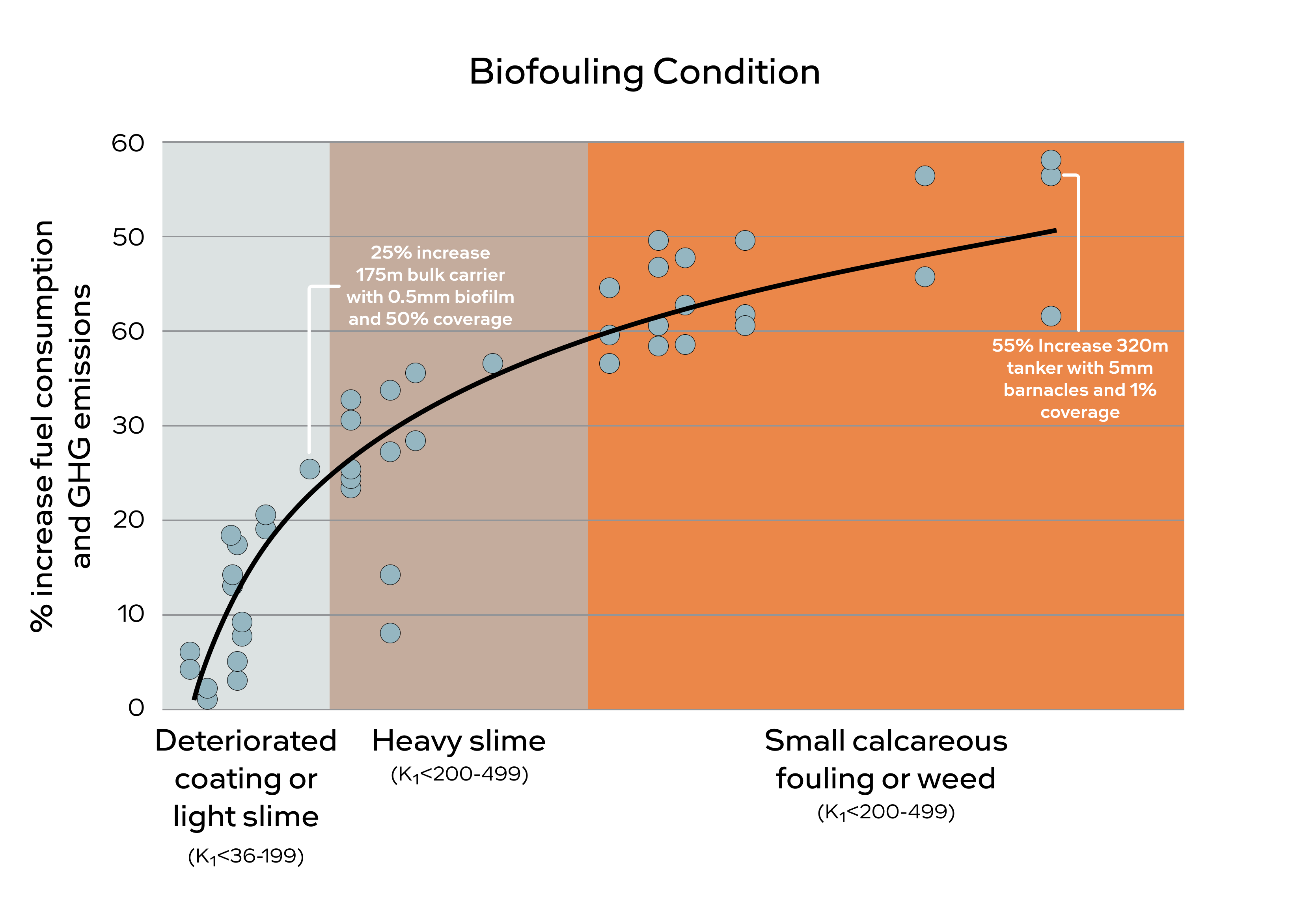

“Even a thin layer of slime just 0.5 mm thick covering 50 % of the hull can increase GHG emissions by 25–30 %,” says Salta, who is also careful to point out the ecological implications. “Importantly, biofouling in shipping is known to facilitate the translocation of non-native (aka alien) species that can have detrimental impact on local biodiversity and ecosystem.”

Needless to say, antifouling coatings are a significant industry sector, which is exactly why independent testing of industry solutions by scientists like Salta is so important.

A report on this particular set of plates was recently published by Endures — the research company which Salta works for — and it sheds some light on the differences between some of the key antifouling technologies available today. So we sat down with Salta to chat about the findings, and about antifouling technology in general.

The research was commissioned by Sailing Yacht Zero, an all-electric, 69-meter-long vessel powered only by renewable energy, which demands that it pays careful attention to every drop of energy used onboard. And, along its construction journey, Sailing Yacht Zero is sharing the findings of all of the research it commissions, so that the industry at large may benefit as well.

And the results of this report hold a lot of value for those considering how their ship’s hull coating choice might affect not just performance, but the marine environment as well. Because it turns out that antifouling, like so many other products we take for granted, also comes with a hidden cost.

The science and history of smooth sailing

Humans have been battling to prevent marine life from growing on the hulls of ships for about as long as we’ve been building them. But the first major scientific breakthrough came in the 1970s with the commercialisation of a new range of antifouling products called Self Polishing Copolymers (SPCs). SPCs made it possible to incorporate a biocidal chemical called Tributyltin (TBT) in such a way that it was released in small amounts as the paint intentionally erodes away over time, thus the term “self polishing”.

Finally, ships had a way of ensuring that their hulls remained both smooth and poisonous — which proved to be extremely effective at deterring all kinds of marine growth from attaching. SPC’s also worked for a prolonged period which reduced the need for reapplication, which is a huge benefit, because repainting the hull of a ship involves the costly process of hauling it out of the water (known as “dry docking”) to remove the growth before repainting.

Unfortunately there was no way of containing this highly potent poison to the ship’s hull, because it was specifically designed to slowly leach from the painted surface. And so in the late 2000s the International Maritime Organisation (IMO) introduced a global ban on the use of TBT in antifouling products — creating the constraints necessary for innovation to thrive.

At this point the industry began experimenting not only with different chemicals to replace TBT, but also with entirely new methods. This was important because despite the variety of potentially less harmful biocides, SPC’s still fundamentally rely on leaching these chemicals into the ocean.

The most successful alternative to SPCs is currently Fouling Release Coatings (FRCs), which use silicone or a fluoropolymer to create an ultra-smooth, extremely low surface energy surface. The smooth surface makes it more difficult for fouling marine organisms to establish themselves - without leaching any biocides into the ocean.

Of course, FRCs have their drawbacks. They typically work better on faster moving vessels where the water flow can dislodge the creatures which still have managed to attach themselves for a free ride, and in some cases FRCs are more expensive. The intended use case and budget of any particular vessel therefore usually determines which technology it will use. But the data from reports like Salta’s is helping to build a strong case for a wider adoption of FRCs.

What exactly is biofouling?

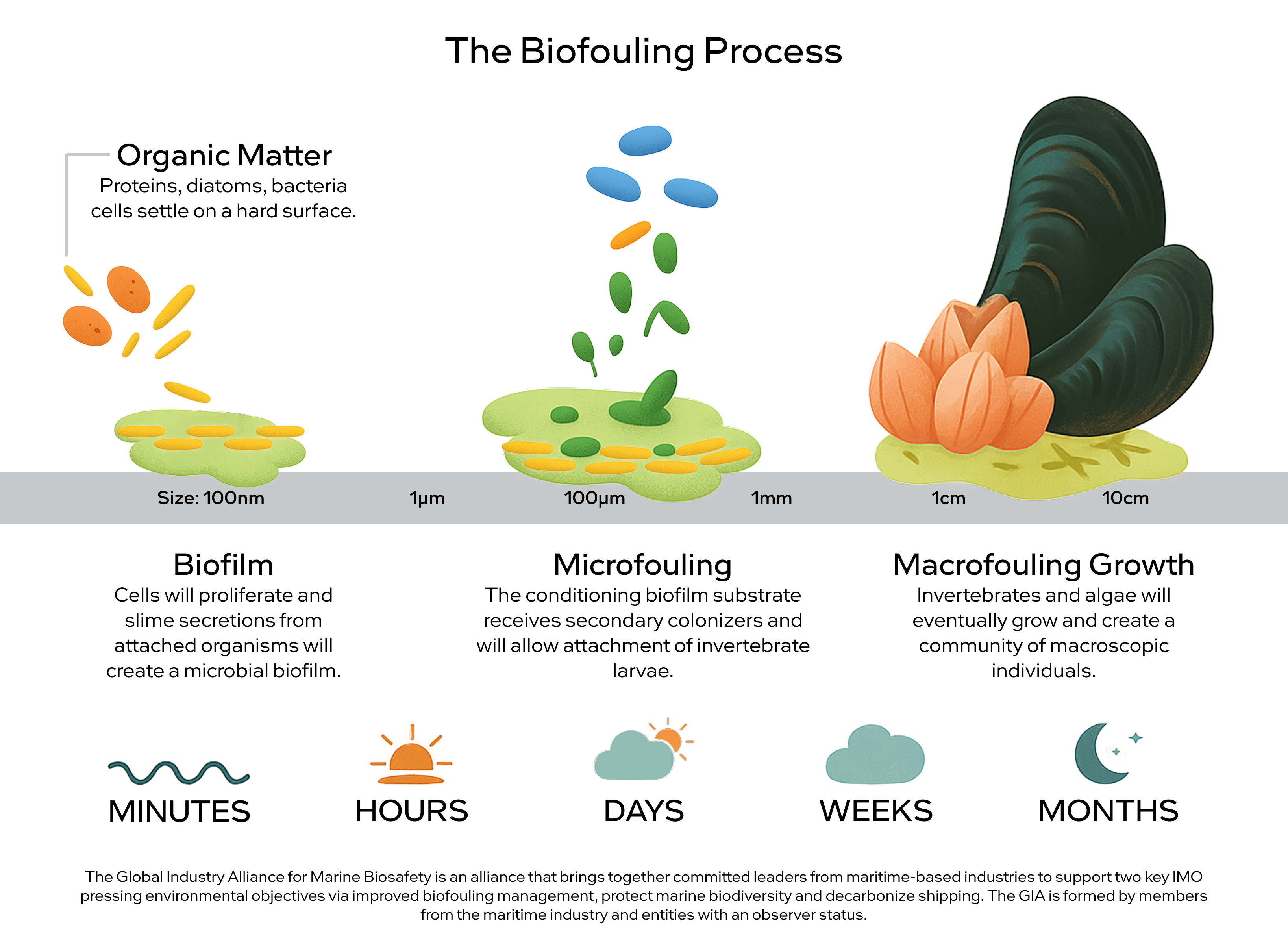

The remarkable process whereby this array of marine life attaching itself to just about any surface submerged in the ocean begins as soon as the object hits the water. It’s known to the industry as ‘biofouling’.

“It starts from the creation of a small biological layer – also called biofilm, slime or microfouling – that quickly (within minutes to hours) attaches to a newly immersed surface,” explains Salta. “Within days, other microorganisms such as spores and larvae are following, often attracted by that first biofilm layer which serves as a food source, and establish themselves.”

As months go by and the larvae and spores grow into large complex communities, organisms visible to the naked eye will begin to appear. Some have names so bizarre they sound almost alien, like bryozoans and hydroids. But eventually organisms whose names aren’t out of place on a seafood menu, such as mussels and oysters, will also find their way into the mix.

And by the time these have appeared on the hull of a ship, the impact on water resistance can become extreme. “More severe biofouling, such as small calcareous growths, can raise emissions by up to 60 %, and in the case of medium calcareous fouling, emissions may increase by as much as 90 %,” says Salta.

Just imagine if you had to use almost double the amount of fuel to drive home from your holiday destination as you did to get there, all because a bunch of grass and insects colonised your car’s paintwork!

Ironically this fouling process is the same one involved in the critical process of reef formation and involves an extraordinary amount of cross species co-operation. Some industries are even taking inspiration from the biofouling process. Barnacle cement for example, the name given to the natural adhesives which barnacles produce, is able to adhere to almost any surface while being submerged in a saltwater solution, a feat which synthetic adhesives struggle to replicate and which scientists in other fields are now trying to learn from.

Defining and measuring antifouling performance

As is the case with so many natural processes, accurately measuring the effects of interventions is extremely difficult. “The great variability that is inherently found within the marine environment often limits extrapolations of results” notes Salta. But, by including multiple samples and doing a variety of different tests in the North Sea environment, Salta and her team have developed a method which produces a compelling set of results.

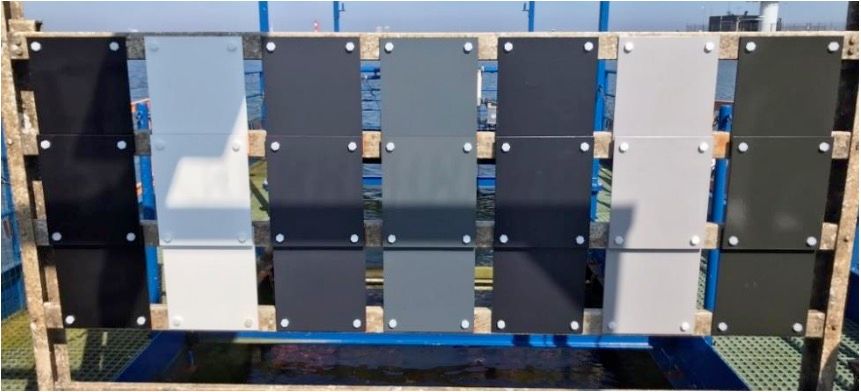

The first of these tests involves coating a number of panels and leaving them submerged in the harbour for up to 12 months. Regular inspections are done to visually quantify the marine growth which has taken hold compared to a control group which had no antifouling coatings applied.

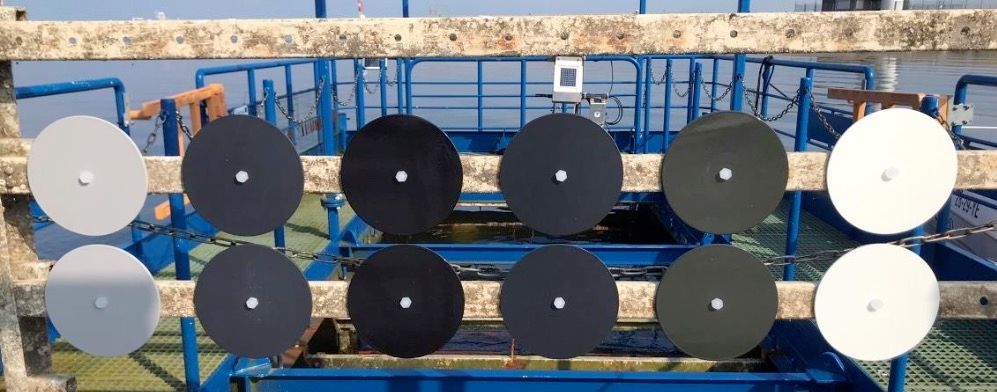

The second test exposes the coatings to dynamic conditions by using a specialised rig developed by Endures to spin the collection of coated metal discs in containers which are continually refreshed with seawater from the harbour. The constant spinning during the aging process simulates a moving ship. A variety of tests are then performed on these discs before and after the ageing process to evaluate how the coating’s thickness, roughness and resulting drag coefficient have changed.

At the same time, a separate set of disks are exposed on the static raft before being subjected to the same tests as above. This allows Salta to evaluate the impact of marine growth on water resistance across the different conditions for the various antifouling technologies.

Old vs New - how do the results look?

Salta is careful to point out the limitations of each experiment in the report, and of course only a limited number of products were chosen which were being considered by Sailing Yacht Zero. But the overall outcomes clearly favoured the performance of the low-surface-energy approach of FRCs over the chemical-leaching method of SPCs.

For the dynamic tests performed on the aged discs, the best performing FRC coating required an initial torque increase of only 5 % while the worst performing SPC coating required a torque increase of over 200 %. Of course there were worse performing FRCs and some better performing SPCs in the dataset but the remarkable performance of some of these new generation coatings is an encouraging result for the future of the technology and the sector in general.

The picture below shows the statically exposed panels after 6 months of immersion, and here too the stark difference between the various panels is a good visual clue which supports the results from the water resistance tests mentioned above.

These results demonstrate the promising potential of newer technologies to tackle the long standing antifouling challenge while also minimising the impact on the marine environment. Salta notes, “Some of the new generation coatings performed extremely well giving hope for prolonged efficacy against biofouling. It would be interesting to follow these coatings for longer periods of exposure time.”

What’s next?

Although FRCs are still the most popular alternative to SPCs, there are also a number of other technologies which might become viable alternatives in the future. Emerging solutions range from advanced surface treatments to underwater robots that perform old-fashioned, mechanical cleaning with brushes to remove growth.

If robotics continues to develop at its current pace, especially with the rapid improvements in machine vision enabled by AI, we may one day live in a world where cargo ships are cleaned by swarms of autonomous underwater robots in the same time it takes to unload their containers. No chemicals required.

Salta is particularly excited about a concept called biomimicry: “Often, the solution comes from the source of the problem. I believe some marine organisms have evolved defence mechanisms against biofouling and these are worth exploring. After all, a considerable amount of biotechnological advances do come from marine organisms… Alas, it is extremely challenging to deconvolute the exact mechanisms of action.”

Salta believes that the future of the technology also hinges on “a wider and hopefully more open dialogue between manufacturers, shipyards, shipowners, and innovators”. A collaboration that could bring more promising solutions from the lab to the hulls of ships.

Either way it seems that the industry is finally shifting to a double-edged approach that addresses greenhouse gas emissions while acknowledging the hidden cost of chemical leaching — the bill for which has historically been picked up by the marine environment and its ecosystems.